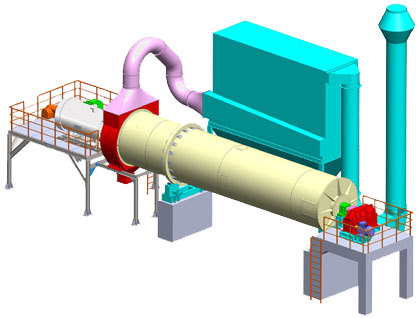

Rotary Dryer

In the dry grinding process, the raw material must be fed into the mills without humidity. Otherwise aggregation may occur inside the mill between the raw material and the grinding media, which will certainly decrease the efficiency of the grinding. Therefore, we always aim for less than 1% feeding humidity with our products.

With the double tube rotary dryers that we produce at REMAS, higher capacity and higher efficiency production is achieved despite using less area.

The raw material is fed to the inner tube of the dryer, and after passing through the inner tube, at the opposite end of the feeding side the material flows to the outer tube. The drying process continues on the outer tube, while the material inside flows to the feeding end with the help of the appropriate designed and positioned dryer wings. The dried material is obtained at the same side of the dryer with the feeding. The dried material can then be transferred to the storage silos with transfer piping.

Together with high efficient burners that also allow of the usage of alternative fuels (natural gas,diesel,kerosene), dual- fuel burners, direct drive system or geared drive systems, covered with high density isolation and double side embedded dryer body, our double tube rotary dryers are designed for continuous, high efficiency production.