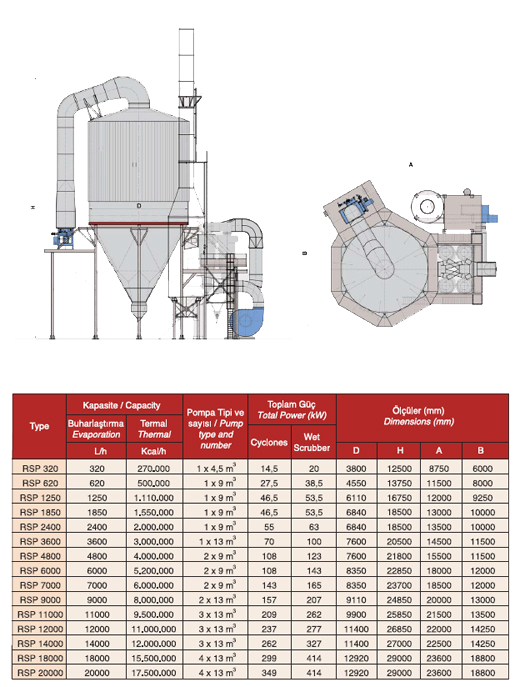

Spray Dryer

Drying the ceramics suspension is the last stage of body preparation. Obtaining and maintaning constant humidity and optimal granule geometry for the granules is extremely cruical.

REMAS spray dryers provide a perfect drying solution by implementing these tenets;

-

Lower energy consumption

-

Burners with high efficiency and lower fuel consumption

-

High efficient fans ensure the effective air flow of the hot air

-

Special design of high quality stainless steel cyclones provide low air pressure loss and maximum efficiency

-

High density isolation to keep the loss of heat to a minimum

-

Adjustable nozzles and removable lances without stopping the system

-

Long duty life and long maintenance intervals

-

Suitable system designs for different type of fuels suitable for cogeneration

-

Different solutions for dedusting system (wet scrubber / bag filter)

Energy consumption efficiency is one of the main necessities to be successfully competitive in the modern market. In line with this, we propose different cogeneration system solutions for heat recovery, such as:

-

Feeding the turbine exhaust back into the system

-

Kiln cooling air can be used

-

Kiln exhaust gas can be used with spray dryer (together with flue gas desulfurization system)

* Dimensions and the values may vary depending on the production and the lay-out